Cereal & Granola

Enhancing Cereal & Granola Production with Vibration Technology

In the cereal and granola industry, vibratory equipment plays a vital role in maintaining consistent quality and streamlining production processes. Vibratory conveyors gently and efficiently transport cereal grains through various production stages without causing damage.

Vibrating screens are utilized to accurately sort and grade cereals based on size, quality and type, ensuring uniformity in the final product. Furthermore, vibratory feeders enable a controlled and steady flow of cereals and granola, which is essential for smooth packaging and processing. The integration of vibratory technology ensures increased precision, productivity and hygiene in cereal and granola manufacturing environments.

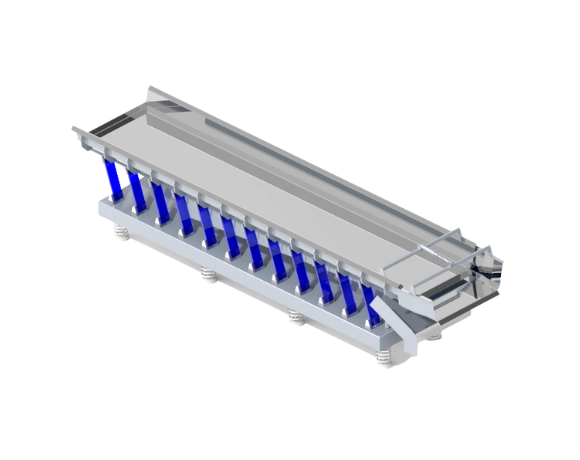

Electromagnetic Conveyor

Our Electromagnetic Conveyors ensure smooth and stable transfer of cereals and granola across different processing stages. Designed for long-distance conveying, they maintain consistent product flow without vibration transfer, ensuring reliable and efficient operations.

Electromagnetic Screening

Electromagnetic Screening provides precise separation of fine cereal particles and granola ingredients. By removing impurities and ensuring accurate sizing, it helps improve product quality, consistency and overall processing efficiency.

Motorised Screening

The Motorized Screening system uses advanced vibration technology to separate cereals and granola by size with high accuracy. Its energy-efficient design supports better classification, improved product quality and higher throughput.

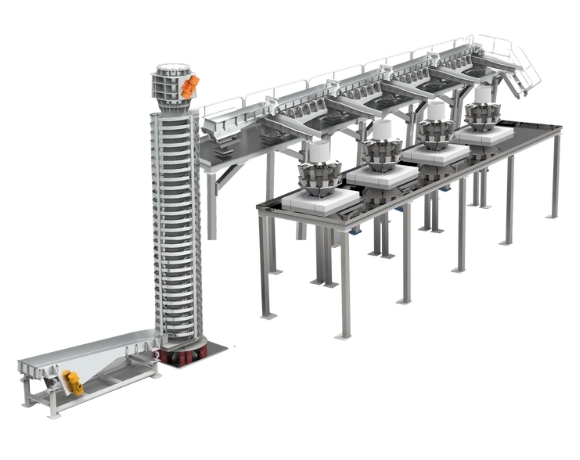

Vibratory Distribution System

Our Vibratory Distribution Systems deliver cereals and granola evenly to multi-head weighers, boosting packaging speed and accuracy. With hygienic design, quick changeovers and minimal downtime, they ensure consistent output and faster returns on investment.

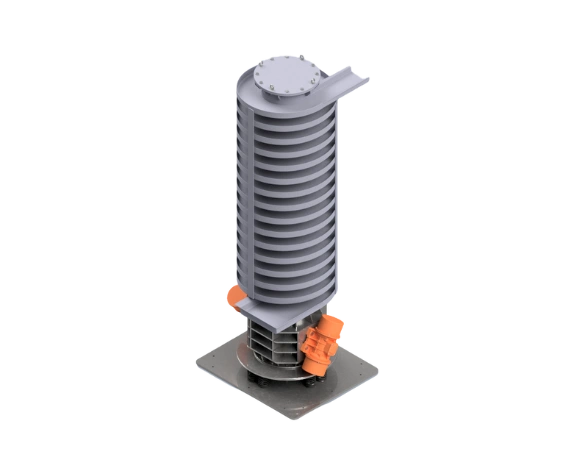

Vibratory Spiral Elevator

The Vibratory Spiral Elevator is ideal for elevating cereals and granola vertically within limited space. Perfect for cooling, drying and gentle handling, it maintains product integrity while saving floor space. Its stainless-steel design is durable, easy to clean and energy efficient.

Vibrating Spreader

The Vibrating Spreader ensures even distribution of cereals and granola across processing lines. With a handling capacity of 1–5 TPH, its compact, customizable design improves process efficiency and product uniformity.

Why Choose Us

We deliver reliable, hygienic and efficient solutions trusted by leading industries. Your success is our priority.