Grains

Reliable Systems for Clean Grain Operations

In the grains industry, vibratory equipment plays an important role in improving the overall processing system. Shri Vibracion Technologies, a leading manufacturer of grain processing machines and grain & seed cleaning equipment, produces machines like vibratory feeders, conveyors, screening systems, spiral elevators, compaction tables and weighing systems to handle grains more efficiently.

These machines help control the flow of grains, prevent damage during transfer and separate grains based on size or quality. Spiral elevators are especially useful for moving grains vertically without breakage. Compaction tables help in packing and weighing systems ensure accurate quantities. Together, they make grain processing faster, smoother and more reliable, while maintaining high quality and reducing product loss.

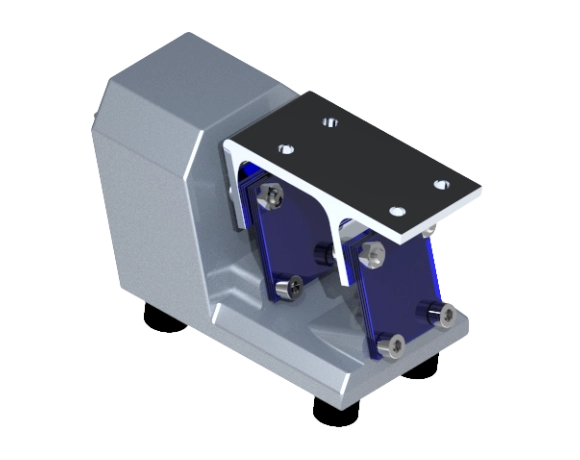

Electromagnetic Screening

Electromagnetic Screening ensures high-precision separation of grains using an electromagnetic mechanism. It effectively removes dust and other impurities, improving grain quality and boosting processing efficiency.

Electromagnetic Feeder

The Electromagnetic Feeder provides smooth and consistent grain flow with adjustable speed control. Available in capacities from 1 TPH to 20 TPH, it ensures precise feeding in packaging machines, rice sheller machines, and color sorters, making processing and packaging operations stable, efficient and reliable.

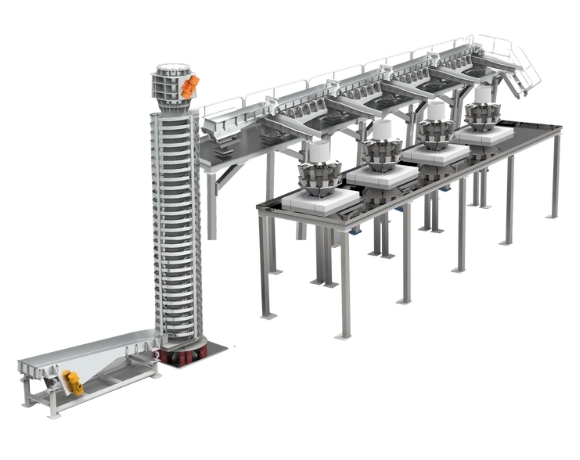

Vibratory Distribution System

Our Vibratory Distribution System ensures uniform grain flow to weighing and packing units. Designed for efficiency and minimal downtime, it improves output consistency and helps maintain high productivity in grain handling.

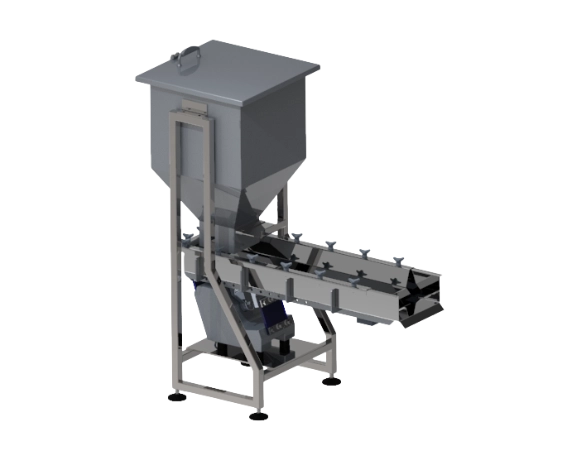

Volumetric Feeder Set

The Volumetric Feeder Set delivers grains in fixed, accurate volumes. It ensures steady flow during mixing, conveying, or packaging, reducing waste and improving efficiency. Customizable for different flow rates, it adapts easily to various grain processing needs.

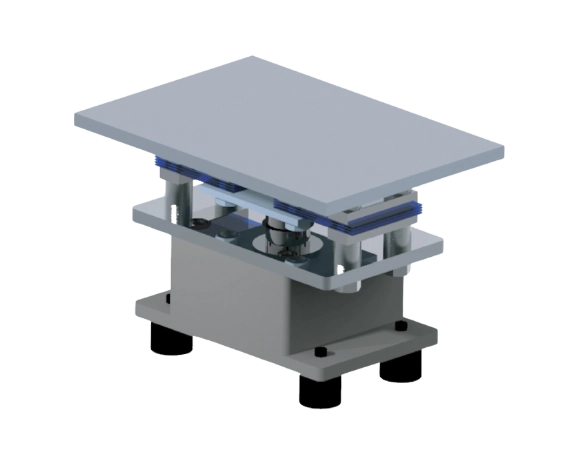

Compaction Table

The Compaction Table uses vibration to settle grains evenly by removing air gaps. This ensures denser, more stable filling during storage or packaging, improving handling and reducing spillage. Available in different sizes and vibration strengths for specific grain operations.

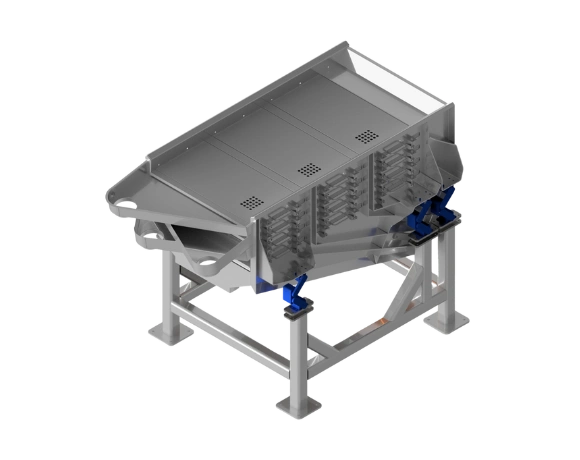

Multi-deck Screening

Multi-deck Screening systems separate grains by size using 3–5 perforated decks in a single process. They offer precise grading, easy maintenance and high productivity, making them a reliable solution for large-scale grain classification.

Why Choose Us

We deliver reliable, hygienic, and efficient solutions trusted by leading industries. Your success is our priority.