Snacks

Snack Food Processing Equipment and Handling System

Shri Vibracion Technologies provides high-quality and dependable systems specially made for the smooth conveying, seasoning and handling of a wide variety of snack and namkeen food items like potato chips, aloo bhujia shev, farsan, chakli, kurkura, extruded snack food and more. Our snack food machines are built to make processing easier, faster and more efficient.

As a trusted snack processing equipment manufacturer, we design equipment that helps improve snack production, reduce waste and ensure consistent results. Widely used by professionals in the snack food industry, our solutions deliver reliable performance you can count on every day.

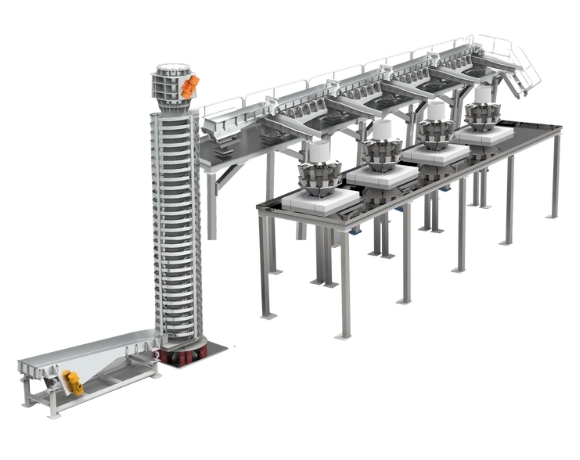

Vibratory Distribution System

Our Vibratory Distribution System keeps snacks and namkeen moving smoothly to multi-head weighers, ensuring even product flow and accurate filling. Equipped with a magnetic rod arrangement, sensors and automatic on/off gates, it supports fully automated operations. With quick changeovers, easy cleaning and minimal downtime, it helps you pack faster, maintain hygiene, and maximize returns on investment.

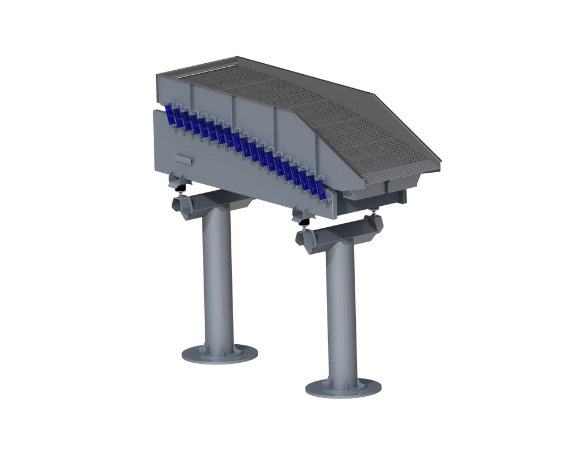

Electromagnetic Screening

The Electromagnetic Screening System gently separates snack ingredients by size while removing impurities like broken chips and fine particles. Ideal for pulses, namkeen blends and dry snacks, it ensures clean, uniform quality before seasoning, frying, or packaging stages.

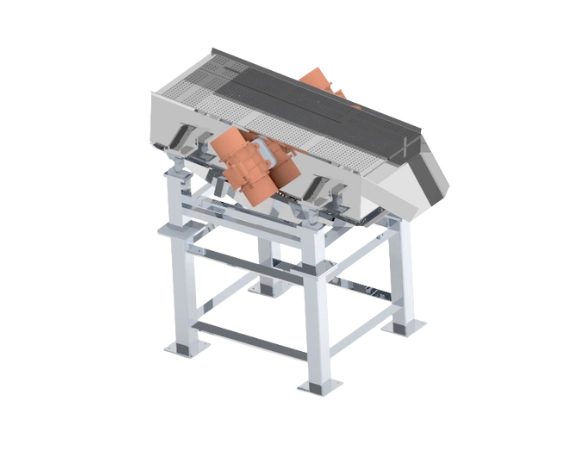

Dewatering / De-aqua Shakers

The Dewatering Shakers efficiently remove excess water from potato slices and other snack products before frying or freezing. This improves fryer efficiency, reduces oil usage and ensures crispier, consistent and high-quality snacks with better texture and reliable processing performance.

De-Oiling Shaker

After frying, snacks often carry excess oil. Our De-Oiling Shaker reduces surface oil and removes fine particles, keeping snacks light, crunchy and clean. With low noise, reliable performance. it’s perfect for flexible snack processing lines.

Loss in Weight Feeder

The Loss-in-Weight Feeder delivers precise seasoning or coating powders to snack lines. By accurately controlling flow rates in real time, it ensures every batch of snacks gets the right amount of flavoring, reducing waste and keeping taste consistent.

Seasoning Conveyor

For perfect snack seasoning, this conveyor spreads powders evenly over products with controlled electromagnetic flow. With customizable lengths and digital controls, it ensures snacks get uniform flavor coating, every time.

Why Choose Us

We deliver reliable, hygienic and efficient solutions trusted by leading industries. Your success is our priority.