Product Groups

Our Products

Shri Vibracion Technologies Pvt. Ltd.” formerly known as Shri Vibracion engaged as the foremost manufacturer of Horizontal Vibrating Conveyor and Electromagnetic Feeder established in the year 2017 at Pune, Maharashtra, India

SVTPL has installed 1000+ units since 2017 for various applications in different industries like Snacks, Grain, Food, Pharma, Chemical, Mineral, Packaging and many more

Our diverse range including Feeders, Conveying, Elevating, Grading, Aligning, Part Handling equipments, System Integration, Pre-Cleaning, Dewatering, length and size grading, Screening, Inspection Belt, Gyro shifter and Customized solutions.

Conveying

At SVTPL, we design smart, efficient systems for handling all types of materials—from delicate food to heavy industrial goods. Our innovative conveyors, including vibratory, motorized, and HD Flex models, serve industries like food, pharma, chemicals, and many more with precision and hygiene.

Elevating

Effortlessly elevate fragile products with our spiral elevator—ideal for snacks, dry fruits, frozen foods & plastics. Built from stainless steel for hygiene and durability, it cools, dries, and conveys vertically up to 6m. Compact, space-saving, and gentle, it handles up to 2 tons/hr with customizable sizes—perfect for multilevel production lines.

Screening

Achieve precise material separation with our advanced screening systems. Designed to ensure quality and efficiency, we offer electromagnetic and motorized options tailored to diverse industry needs. These systems remove impurities, sort by size, and deliver consistent, reliable performance.

Seasoning

Our Electromagnetic Seasoning Feeder ensures uniform powder flow to flavoring drums, ideal for snacks and nut products. It provides even coating, enhancing flavor consistency. Available in 1–3 meter lengths with customizable troughs and scarf cuts, it fits various needs. A Digital Frequency Controller offers precise control for accurate seasoning application every time.

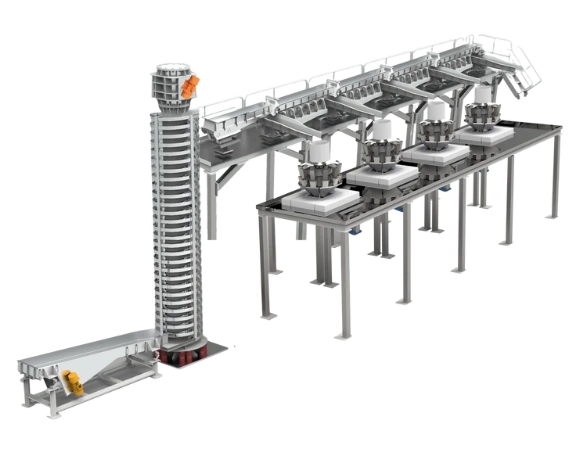

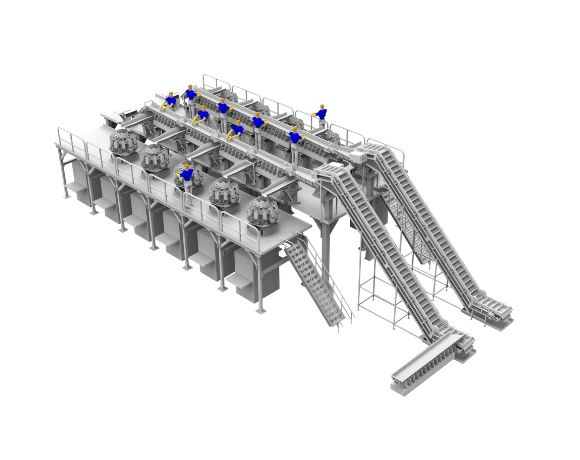

Automation & Integration

Our automation and integration systems boost efficiency, reduce errors, and ensure consistent quality across production. Designed to fit seamlessly into existing lines, they improve material flow, reduce labor, and support faster ROI. From vibratory distribution to advanced mixing and weighing, our solutions are tailored to meet diverse industrial needs with reliable performance and minimal waste.

Turnkey Projects

We provide complete turnkey solutions tailored to your industry. From design to commissioning, we integrate material handling, screening, grading, conveying, weighing, and packaging into a seamless flow.

With expertise in snacks, IQF, pharma, dairy, grain processing and more, we customize layouts and equipment to ensure hygiene, efficiency, and consistency.

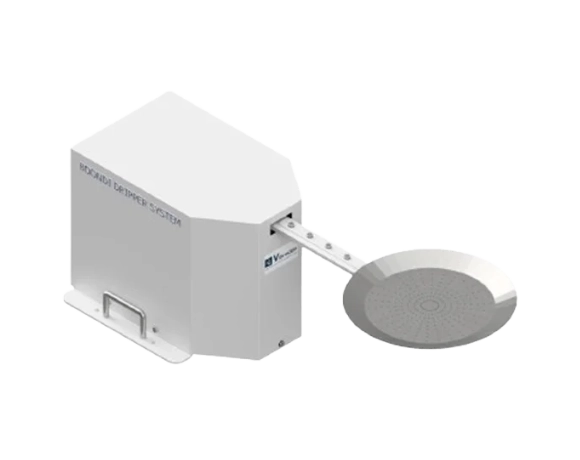

Special Purpose Machines

Our Part Handling Systems are tailored to meet the specific material handling needs of various industries. From the automated Boondi Dripper System that boosts snack production to efficient Compaction and Bowl Systems for granules, metals, and plastics—each solution is designed for improved performance, reduced labor, and smooth operations. Backed by ongoing R&D, our systems ensure reliability and efficiency.

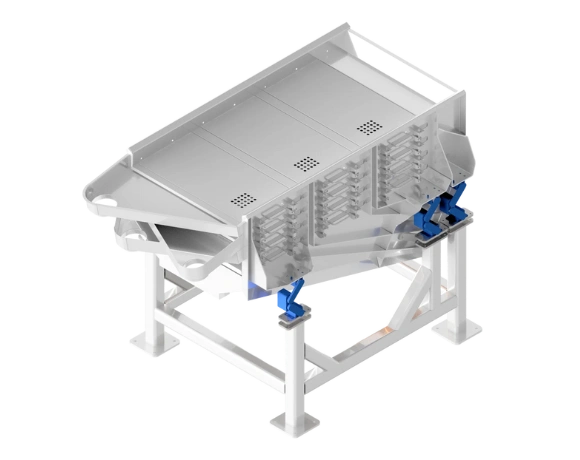

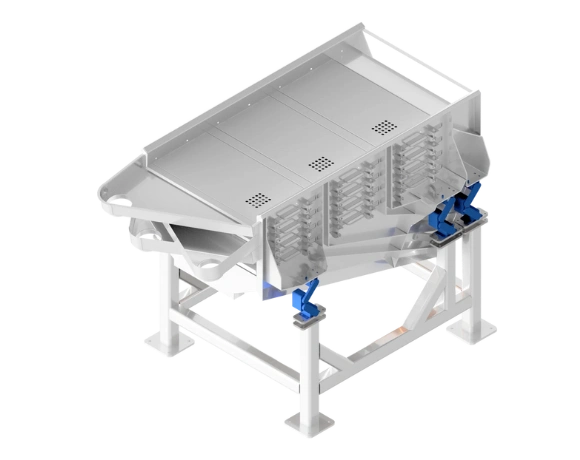

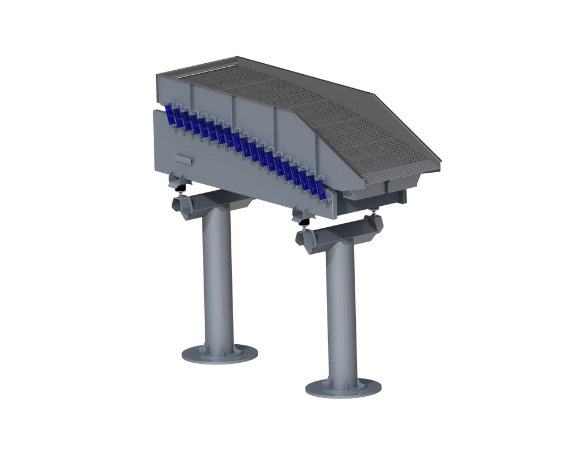

Vibrating Shakers

Our vibrating shakers help make production faster and more efficient by removing extra water, oil, or fine particles from your products. They improve fryer and freezer performance, keep materials uniform and ensure consistent quality throughout the process.

Built for flexibility and reliability, these shakers adapt to different materials and production lines. Whether it’s drying, de-oiling, or spreading, they help keep your operations clean, efficient and running without interruptions.

Solutions for Various Industries

Serving a wide range of industries with tailored solutions that meet unique operational needs and standards.

Why Choose Us

We deliver reliable, hygienic, and efficient solutions trusted by leading industries. Your success is our priority.